Air, Water & Auxiliary Systems

Supporting Sustainable & Efficient Plant Operations

- Overview

At 3SEngitech, we deliver comprehensive utility and auxiliary systems that keep steel plants, rolling mills, and foundries running efficiently and sustainably. From advanced Air Pollution Control Systems (APCS) to Water & Cooling solutions, Scrap Handling equipment, and Material Conveyors, we integrate the backbone systems that improve plant safety, environmental compliance, and productivity. Each system is designed with reliability, energy efficiency, and ease of maintenance at its core, ensuring long-term performance in the most demanding industrial environments.

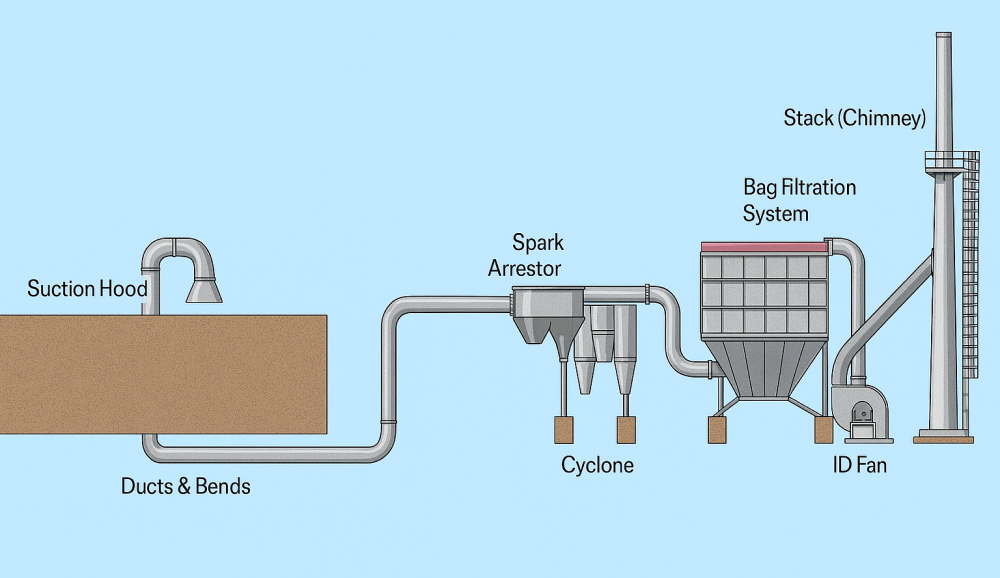

Air Pollution Control Systems (APCS)

We design and install pollution control systems that help industries meet environmental standards while improving workplace safety. Our APCS solutions remove dust, fumes, and secondary emissions from furnaces and other processes, protecting both equipment and people.

What We Do:

Design and supply Bag Filters, Venturi Scrubbers, and Cassette Filters.

Dust Collection Systems for furnaces, slag handling, and casting operations.

Stack monitoring systems with CPCB/USEPA-compliant measurement methods.

Screw conveyors for efficient dust handling and safe disposal.

Forced Draught Coolers for gas cooling from 1200°C to 250°C.

Water Treatment Plants (WTP)

Steel plants consume massive amounts of water for cooling, dust suppression, cleaning, temperature regulation, and waste transport. This generates large volumes of wastewater with suspended solids, dissolved chemicals, and impurities. Our advanced Filtration & Treatment Plants are designed to recycle and purify water in Continuous Rolling and Continuous Casting Mills, ensuring efficiency, compliance, and cost savings.

Advantages:

Reduced Turbidity & TSS – Cuts pump and pipeline maintenance by over 50%.

No Scaling or Fouling – Extends equipment and pipeline life significantly.

Longer Roller Pass Life – Increases by 20–25%, boosting profitability.

Less Frequent Draining – Annual draining instead of every 2–3 months saves costs.

Improved Cooling Tower Efficiency – Higher heat transfer rates, reduced power consumption, longer life.

Reduced Scale Formation – Prevents nozzle choking and corrosion in caster machines.

Industrial Air Conditioning Unit (I-AC)

Our Industrial Air Conditioners are engineered to cool panel rooms and maintain safe operating temperatures for PLC banks and control panels. Designed in-house, these units perform reliably even in highly dusty and demanding industrial environments, ensuring continuous protection of critical electrical systems.

Features:

- No ducting required for installation.

- High efficiency under varying loads and harsh conditions.

- Available in a wide capacity range from 2TR to 15TR.

Applications:

Steel Plants | Rolling Mills | Sugar Industries | Cement Industries | Automobile Industry | Coal & Mining Industry | Chemical & Pharmaceutical Industry | Warehouses & Other Industrial Facilities

Load Cell for Furnace, Ladle & Tundish

A load cell is a precision transducer that converts force into measurable electrical output. In steel and foundry applications, furnace load cells provide accurate charge weight measurement, simplifying charge calculations, alloy additions, and metal tapping. Integrated with PMA 100 or SPA 100 systems, they enable real-time monitoring of liquid metal weight for enhanced process control and automation.

Advantages:

- Provides reliable and highly accurate weighing, improving productivity and reducing energy losses.

- Enables precise scrap and alloy charging, ensuring chemistry control and better yield.

- Supports temperature prediction and liquid metal maintenance during furnace holding.

- Allows real-time monitoring with alarms, interlocks, and reporting for operators.

- Improves casting accuracy, speed, and ladle sequencing for consistent quality.

- Enhances automation and process efficiency, including slag weight calculation, fume collection, and melting time prediction.

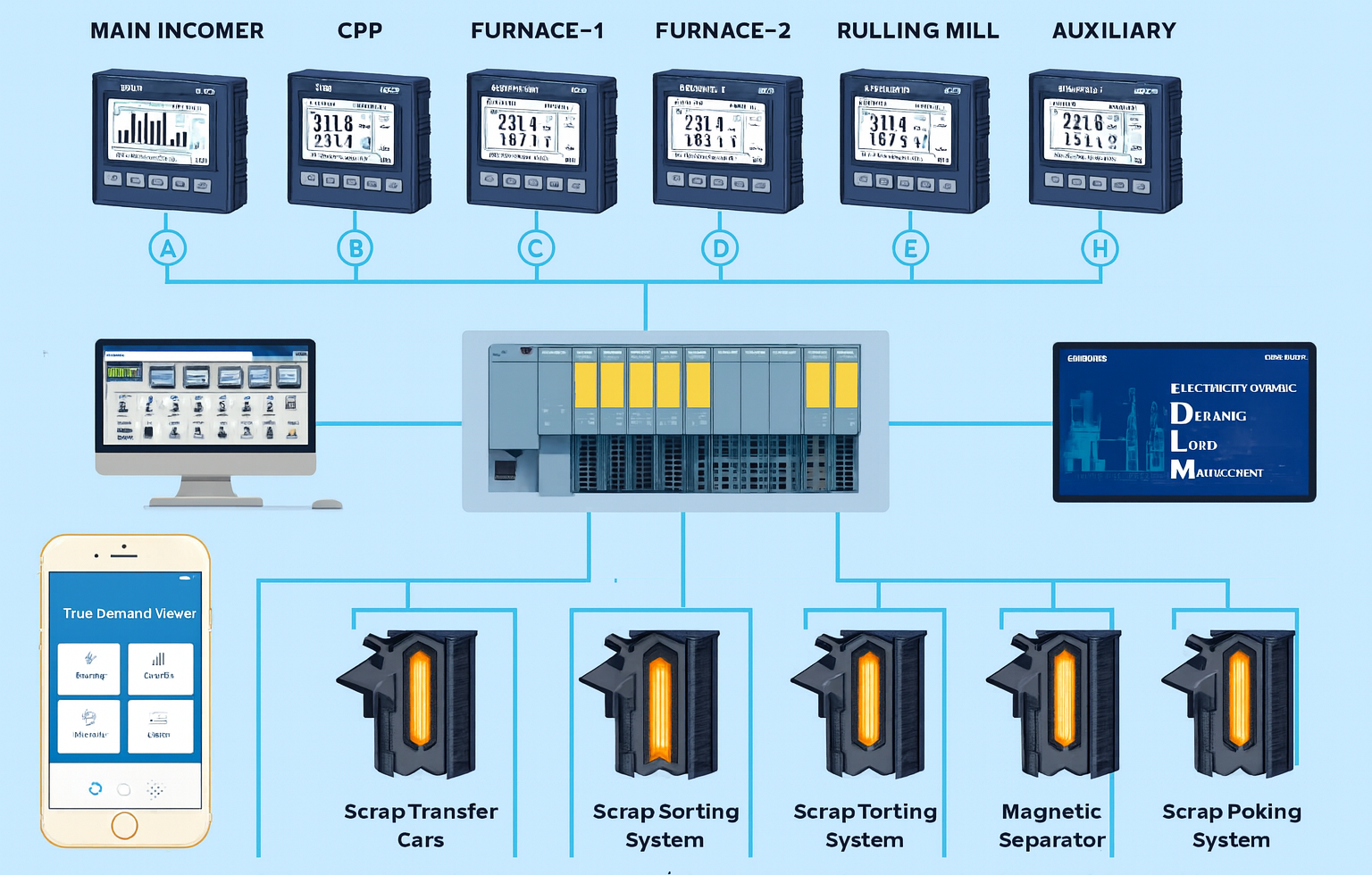

Electricity Dynamic Load Management (EDLM)

EDLM is an intelligent energy-saving device designed to control and maintain the sanctioned demand of a plant. By optimizing power usage and distribution, it enhances efficiency, reduces wastage, and supports higher productivity without exceeding contract limits.

What We Do:

- Maximum Demand Control – Maintains power utilization within sanctioned demand for cost efficiency.

- Load Factor Optimization – Improves machinery utilization and overall plant load factor.

- Production Benefits – Enables better output from the same resources by maximizing KVA utilization.

- Real-Time Monitoring – Plant data available via 7” HMI, SCADA, or remote access through cloud on mobile/laptop.

- Dynamic Load Management – Synchronizes with conventional power and renewable energy systems for balanced distribution.

Power Factor Correction & Harmonics Filtration

In partnership with InPhase, we deliver advanced solutions for power quality improvement. With decades of expertise and installations exceeding 3,50,000 Amps worldwide, our systems ensure reliable, efficient, and process-ready power for industries. From reactive power compensation to harmonic filtration, our solutions are engineered for precision, scalability, and long-term performance.

What We Do:

- Active Harmonic Filters (AHF) – Eliminate harmonic distortions and improve overall power quality.

- Static VAR Generators (SVG) – Provide the best-in-class reactive power compensation.

- Smart Hybrid Active Filters (SHAF) – Combine active and passive filtering for optimized performance.

- RTPFC Systems – Deliver reactive power compensation for dynamic and fluctuating industrial applications.

- APFC Panels – Improve power factor using conventional and cost-effective methods.

Plant Automation Products

Our automation solutions combine energy efficiency, process accuracy, and advanced monitoring to make plants smarter and more productive. From furnaces and casters to APCS and material handling, our systems are designed for seamless integration with Industry 4.0/5.0 requirements.

Product Range:

- Energy-Saving VFD Panels – Panels for casters, furnace pump houses, conveyors, and rolling mills, enabling energy savings and smoother equipment control.

- Control & Monitoring Systems – SCADA, PLCs, HMIs, VFDs, Soft Starters, and Industrial Routers for reliable automation and real-time plant monitoring.

- APCS Automation – Energy-saving systems with stack monitoring, dust level indicators, pneumatic conveyors, screw conveyors, and IIoT integration for emission control and compliance.

- Caster Automation – Billet counting, load cells, and temperature monitoring for accurate casting and process efficiency.

- Furnace Automation – Load cell with power control, automatic converter switching, and intelligent furnace management for higher productivity and energy optimization.

Material Handling Equipment & Conveyors

Efficient material movement is critical to plant performance. We design and supply conveyors and handling systems that improve throughput while minimizing manual effort.

What We Do:

- Screw conveyors for dust and bulk material handling.

- Bucket elevators, screening, and mixing systems.

- Customized belt, chain, and roller conveyors for heavy industry.

- Pneumatic conveying systems: lean phase, dense phase, and closed-loop.

- Centralized vacuum cleaning systems and bulk transfer solutions.

Scrap Handling & Transfer Systems

We provide heavy-duty equipment for handling, transferring, and processing scrap and molten material safely. Built for durability, our systems minimize downtime, improve worker safety, and ensure seamless material flow across steel plants.

What We Do:

- Ladle Cars & Slag Pot Cars – Safe transport of molten metal and slag.

- Scrap Poking System (SPS) – Enables efficient melting of dense scrap inside induction furnaces.

- Scrap Sorting System (SSS) – Includes magnetic separators, eddy current separators, vibratory hoppers, and dust removal for efficient scrap processing.

- Scrap Transfer Cars / Ladle Transfer Cars – Heavy-duty, radio remote-controlled systems for high-capacity scrap handling.

- Customized Scrap Processing Solutions – Sorting, processing, and transfer systems tailored to individual plant requirements.

Furnace, Caster & Plant Spares & Consumables

We provide a complete range of general spares and consumables for induction melting furnaces, casters, steel plants, and rolling mills. Designed for compatibility with all makes and models, our spares ensure smooth operations, reduced downtime, and reliable performance across every stage of production.

What We Offer:

- Furnace coils, crucibles, yokes & water-cooled cables

- Caster load cells, billet counters & temperature monitoring systems

- Pumps, motors, gearboxes, conveyors & control panels

- Carbon-free hoses, insulation materials, capacitors & harmonic filters

- Crane and material handling spares for steel & rolling mills