Industrial Automation & Digital Solutions

Transforming Plants into Digital Factories

- Overview

At 3SEngitech, we enable industries to embrace Industry 5.0 through advanced automation and digital platforms. Our solutions integrate edge-to-cloud connectivity, remote monitoring, asset analytics, smart energy management, and digital twins, ensuring seamless collaboration between humans and machines.

With a strong focus on efficiency, cost reduction, and sustainability, our automation systems help plants optimize energy usage, reduce downtime, and improve asset performance. Whether it’s predictive maintenance, anomaly detection, or KPI tracking, our Digital Factory approach delivers real-time intelligence that transforms decision-making at every level.

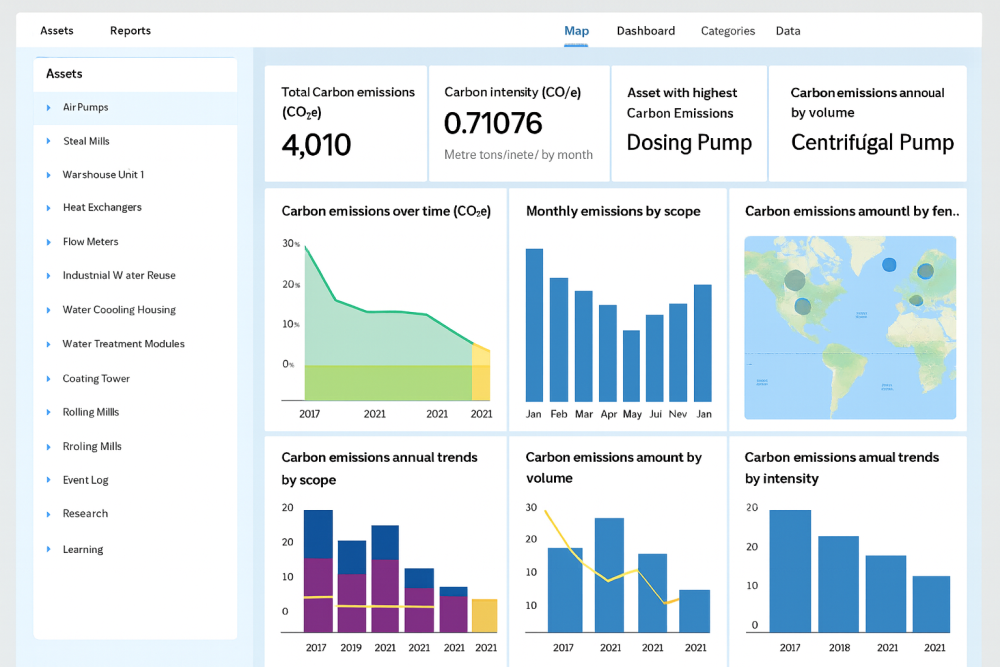

Asset Analytics

Monitor your assets in real time using our Digital Factory platform. Asset Analytics provides efficiency recommendations and supports predictive maintenance for critical equipment.

Key Capabilities:

Real Time Analytics

Anomaly Detection

Integration with other devices

Predictive Maintenance Models

KPI Tracking

Remote Monitoring

Our Remote Monitoring solutions allow industries to supervise critical equipment and plant systems in real time. By integrating edge-to-cloud connectivity, data from machines is collected, processed, and transmitted securely to centralized dashboards. This enables faster decision-making, early anomaly detection, and reduced downtime, while giving managers complete visibility into operations from anywhere.

Key Capabilities:

Provide real-time dashboards for monitoring critical equipment.

Enable remote access and control over industrial systems.

Ensure secure data transmission through industrial gateways and protocols.

Detect anomalies early to prevent unplanned downtime.

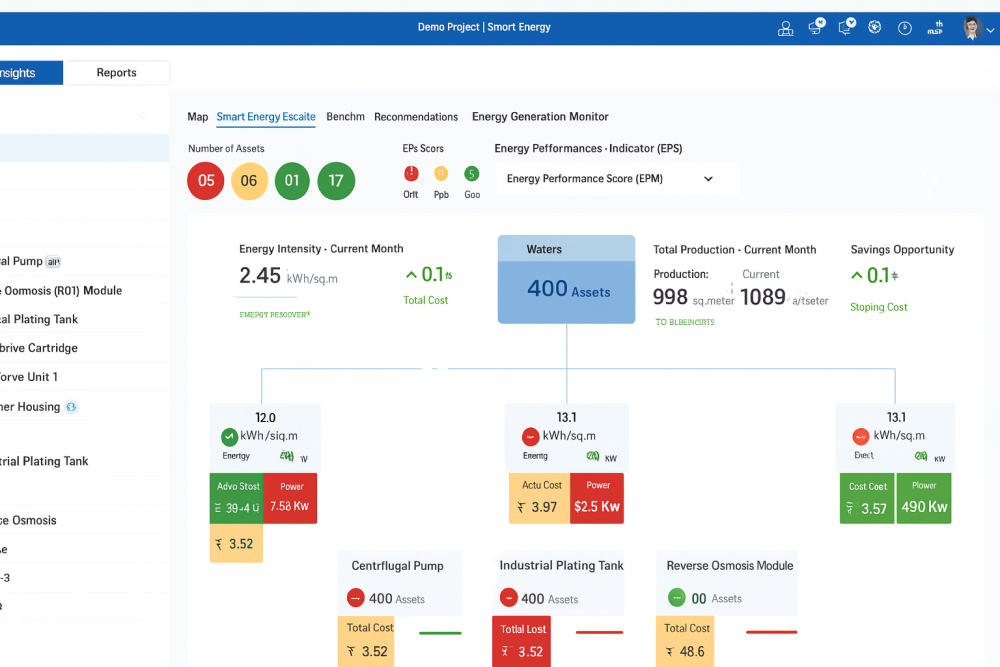

Smart Energy

Cut energy consumption, reduce utility costs, lower carbon emissions, and boost machinery productivity—without adding resources. Our cloud-based Energy Management and Optimization application supports energy cost savings and sustainability goals.

Key Capabilities:

Energy Star EPI Calculations

Loss Calculations with drill-down capability

Critical Asset Energy Efficiency tracking

Anomaly Detection

Benchmarks & Comparison

Energy Recommendations

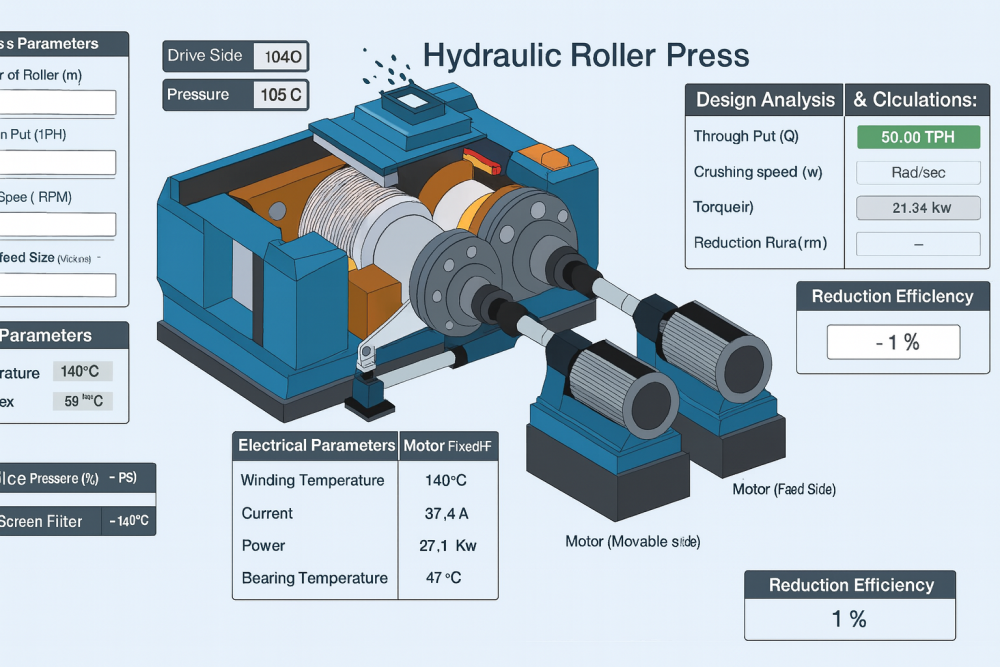

Digital Factory – Human & Machine Intelligence

Our 3S I5.0 solution includes purpose-built apps and web pages designed for each industrial phase and user role, complete with full edge-to-cloud integration.

Cloud-Based Technology

Industrial Knowledge Cloud – Contextualizes data and includes tools for building custom industrial applications.

Edge Manager – Manages remote edge systems, ensuring persistent connections and centralized configuration.

Data Modeling – Normalizes asset and event data to interpret human-machine interactions; pre-defined data models offer quick deployment.

Digital Twins – Visual twins mirror physical assets, enabling performance comparison and anomaly detection.

No-Code App Development – Provide drag-and-drop tools and APIs for creating applications with ease.

Edge

Edge Hardware/Infrastructure – Includes secured industrial gateways, one-way data diodes for IT/OT security, AI appliances, wireless I/O modules, and additional components for specific use cases.

Industrial Knowledge Edge – Software deployable on both our edge infrastructure and third-party IoT gateways, scalable for secure data collection and transmission.

Data Extraction – Supports a range of industrial protocols: OPC DA/UA, Modbus (RTU/TCP/TELNET), Ethernet/IP, OBD II, Siemens Snap 7, 4-20 mA, Profinet/Profibus, HART, CANbus, IEC 101/104, DNP3.

Data Transformation – Enables local processing of raw data to meet app-specific needs.

Data Destination – Pre-configured connectors for routing processed or raw data.

Containerization – Industrial Knowledge Edge runs as a container on various edge infrastructures.